I-HD20 echanekileyo ephezulu yokujonga umgca wekhowudi yokufaka iikhowudi

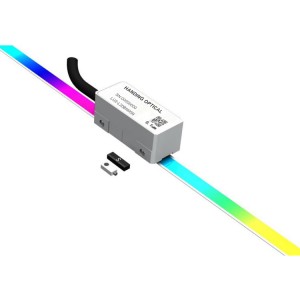

1. Isishwankathelo seMveliso

Ibhanti yentsimbi yokugraya iisixhobo sokulinganisa esichanekileyoyenzelwe umgca kunye nezicelo zokubeka i-angular kumashishini ahlukeneyo. Idibanisa ulwakhiwo oluqinileyo kunye neteknoloji ye-optical ephezulu yokuchaneka okuphezulu kunye nokuthembeka kwexesha elide.

2. Iimpawu eziphambili

Ukuchaneka komlinganiselo ophezulu kunye nokuphindaphinda okugqwesileyo.

Ihlala ixesha elide kwaye iyamelana nemekobume yemizi-mveliso erhabaxa.

Ixhasa ukudibanisa kunye neenkqubo ezizenzekelayo kunye nokulawula.

Uyilo oluphantsi lokugcinwa kweendleko

3. IiNgcaciso zobuGcisa

Izinto:Insimbi engenasici.

IBakala lokuChaneka:±3 µm/m okanye ±5 µm/m (kuxhomekeke kumzekelo).

Obona Bude Bobona bukhulu:Ukuya kuthi ga kwi-50 yeemitha (i-customizable ngokusekelwe kwiimfuno).

Ububanzi:10 mm ukuya kwi-20 mm (iimodeli ezithile zingahluka).

Isigqibo:Iyahambelana neabenzi boluvo bokukhanya okuphezulu(ukuya kuthi ga kwi-0.01 µm ngokuxhomekeke kubumbeko lwesixokelelwano).

Uluhlu lobushushu obusebenzayo:-10°C ukuya kuma-50°C.

Uluhlu lobushushu boGcino:-20°C ukuya kuma-70°C.

I-Thermal Expansion Coefficient:10.5 × 10⁻⁶ /°C.

Amaxesha ekloko:20MHz

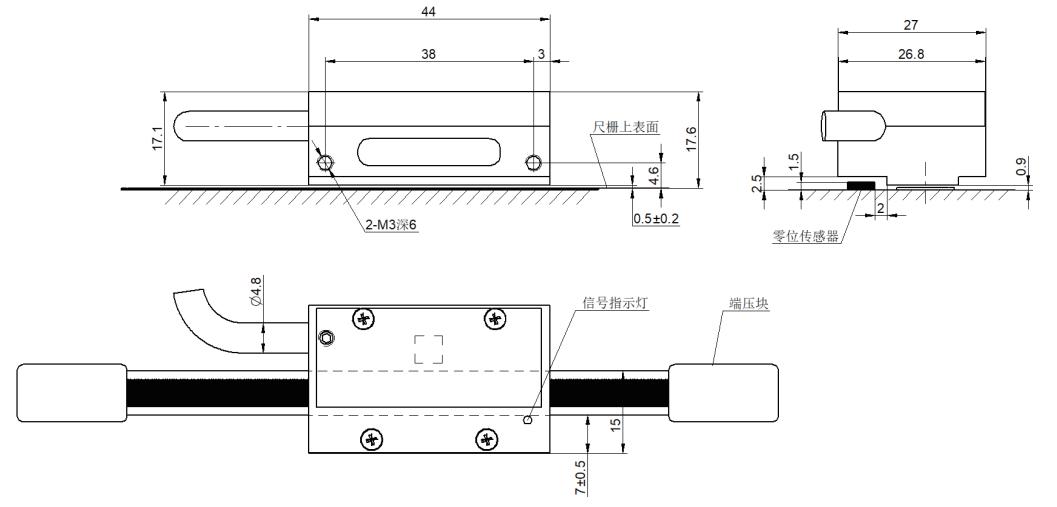

4. Umzobo woMda

Imilinganiselo yentsimbi yentsimbi yentsimbi ichazwe kumzobo wobugcisa, ochaza oku kulandelayo:

Umzimba wokuHluba:Ubude buhluka ngokusekelwe kwimodeli (ukuya kwi-50 yeemitha); ububanzi buphakathi kwe-10 mm kunye ne-20 mm.

iNdawo zokuMounting Hole:Ukulungelelaniswa ngokuchanekileyo kufakelo olukhuselekileyo noluzinzileyo.

Ukutyeba:Ngokuqhelekileyo 0.2 mm ukuya ku-0.3 mm, kuxhomekeke kwimodeli.

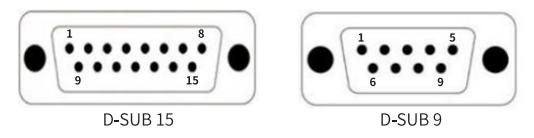

5. Iinkcukacha zeDibanisi ye-D-SUB

Uqwalaselo lwePin:

Iphini loku-1: Ubonelelo lwaMandla (+5V)

Iphini 2: Umhlaba (GND)

Iphini 3: Umqondiso A

Iphini 4: Umqondiso B

Iphini 5: I-Index Pulse (i-Z Signal)

I-Pin 6–9: Igcinelwe ulungelelwaniso lwesiqhelo.

Uhlobo lwesiqhagamshelo:I-9-pin D-SUB, indoda okanye ibhinqa kuxhomekeke kuyilo lwenkqubo.

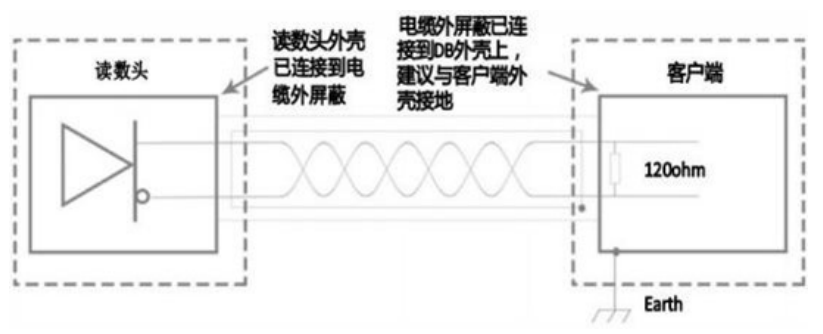

6. Umzobo woMbane woMbane

Umzobo wocingo lombane uchaza unxibelelwano phakathi kwentsimbi yentsimbi kunye nesilawuli senkqubo:

Ukunikezwa Amandla:Qhagamshela iilayini ze-+5V kunye ne-GND kumthombo wamandla olawulwayo.

Imigca Yemiqondiso:I-Signal A, i-Signal B, kunye ne-Index Pulse kufuneka iqhagamshelwe kwiigalelo ezihambelanayo kwiyunithi yokulawula.

Ukukhusela:Qinisekisa ukusekwa okufanelekileyo kwesikhuselo sentambo ukunqanda ukuphazamiseka kombane.

7. Izikhokelo zoFakelo

*Qinisekisa ukuba umphezulu wofakelo ucocekile, uthe tyaba, kwaye awunankunkuma.

*Sebenzisa izibiyeli zokuxhoma ezicetyiswayo kunye nezixhobo zolungelelwaniso ukuze ubeke kwindawo echanekileyo.

*Lungelelanisa igrayiti kunye ne-axis yomlinganiselo, uqinisekise ukuba akukho zijijo okanye ukugoba.

*Kuphephe ukuchanabeka kwizinto ezingcolisayo njengeoyile okanye amanzi ngexesha lofakelo.

8. Imiyalelo yokusebenza

* Qinisekisa ulungelelwaniso olufanelekileyo kunye nolungelelwaniso phambi kokusetyenziswa.

*Kuphephe ukusebenzisa amandla agqithisileyo kwigrayiti ngexesha lokusebenza.

*Beka esweni kuko nakuphi na ukutenxa kufundo kwaye uhlengahlengise njengoko kufuneka.

9. ULondolozo kunye nokuJonga iNgxaki

Ugcino:

*Coca umphezulu wegrayiti usebenzisa ilaphu elithambileyo, elingenantambo kunye nesicoci esisekwe etywaleni.

*Jonga ngamaxesha athile ukonakala komzimba okanye ukungalungelelani kakuhle.

*Qinisa izikrufu okanye izikrufu ezigugileyo endaweni yazo.

Ukulungisa ingxaki:

*Ngemilinganiselo engangqinelaniyo, jonga ulungelelwaniso kwaye uhlengahlengise.

*Qinisekisa ukuba izivamvo zamehlo azinazithintelo okanye ungcoliseko.

*Qhagamshelana nenkxaso yobugcisa ukuba iingxaki ziyaqhubeka.

10. Izicelo

Igrayiti yentsimbi idla ngokusetyenziswa kwi:

*CNC machining kunye automation.

*Iinkqubo zokubeka iirobhothi.

*Izixhobo ze-metrology ezichanekileyo.

*Iinkqubo zokwenziwa kwamashishini.

Iindidi zeemveliso

-

Ifowuni

-

I-imeyile

-

Whatsapp

whatsapp

-

WeChat

-

Phezulu